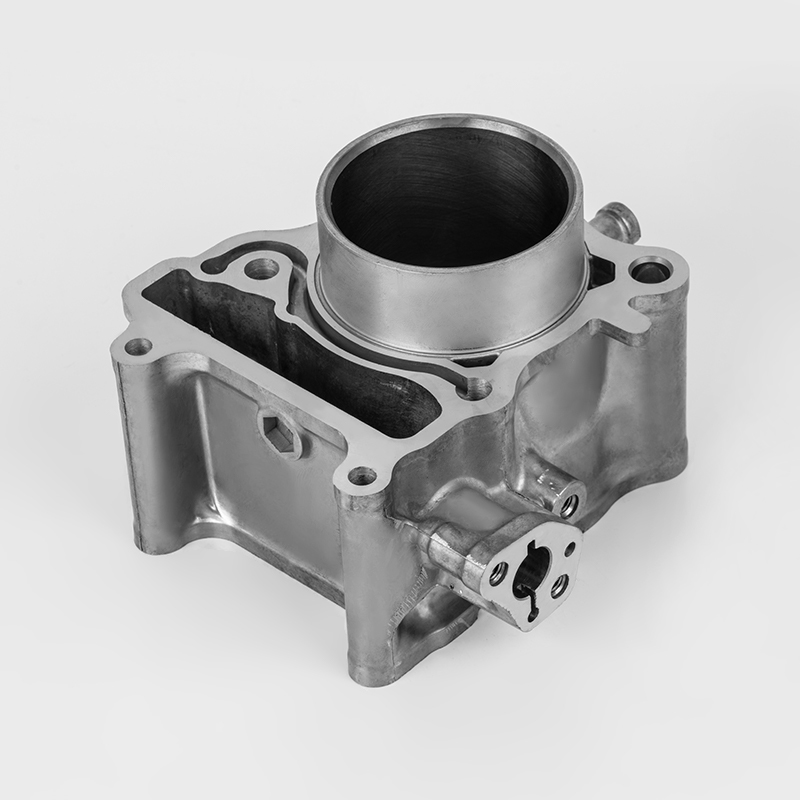

Absolutely, motorcycle cylinders can often be repaired depending on the type and severity of damage. Here's a practical breakdown:

Content

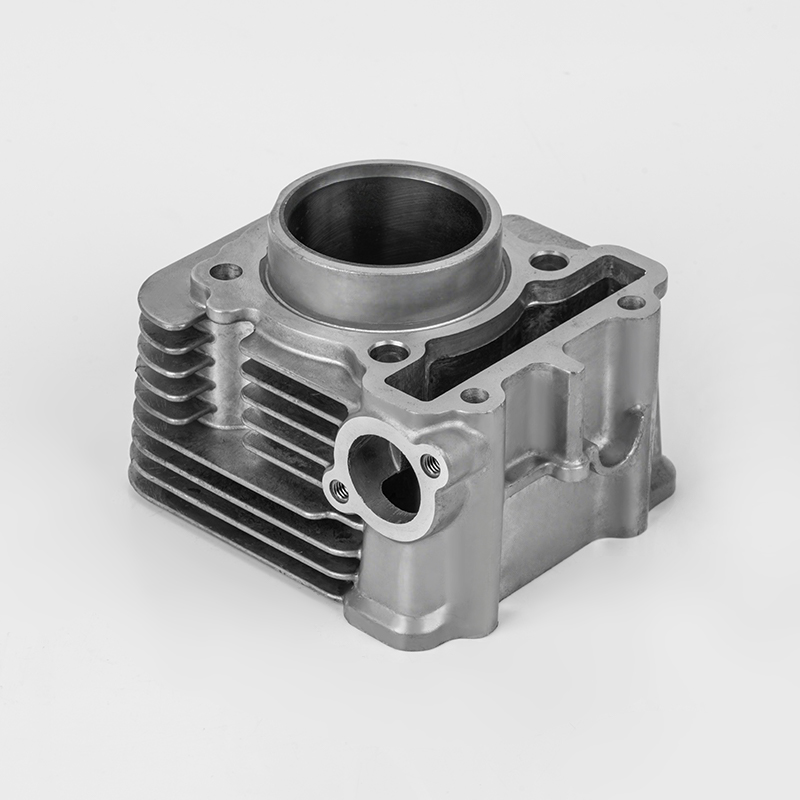

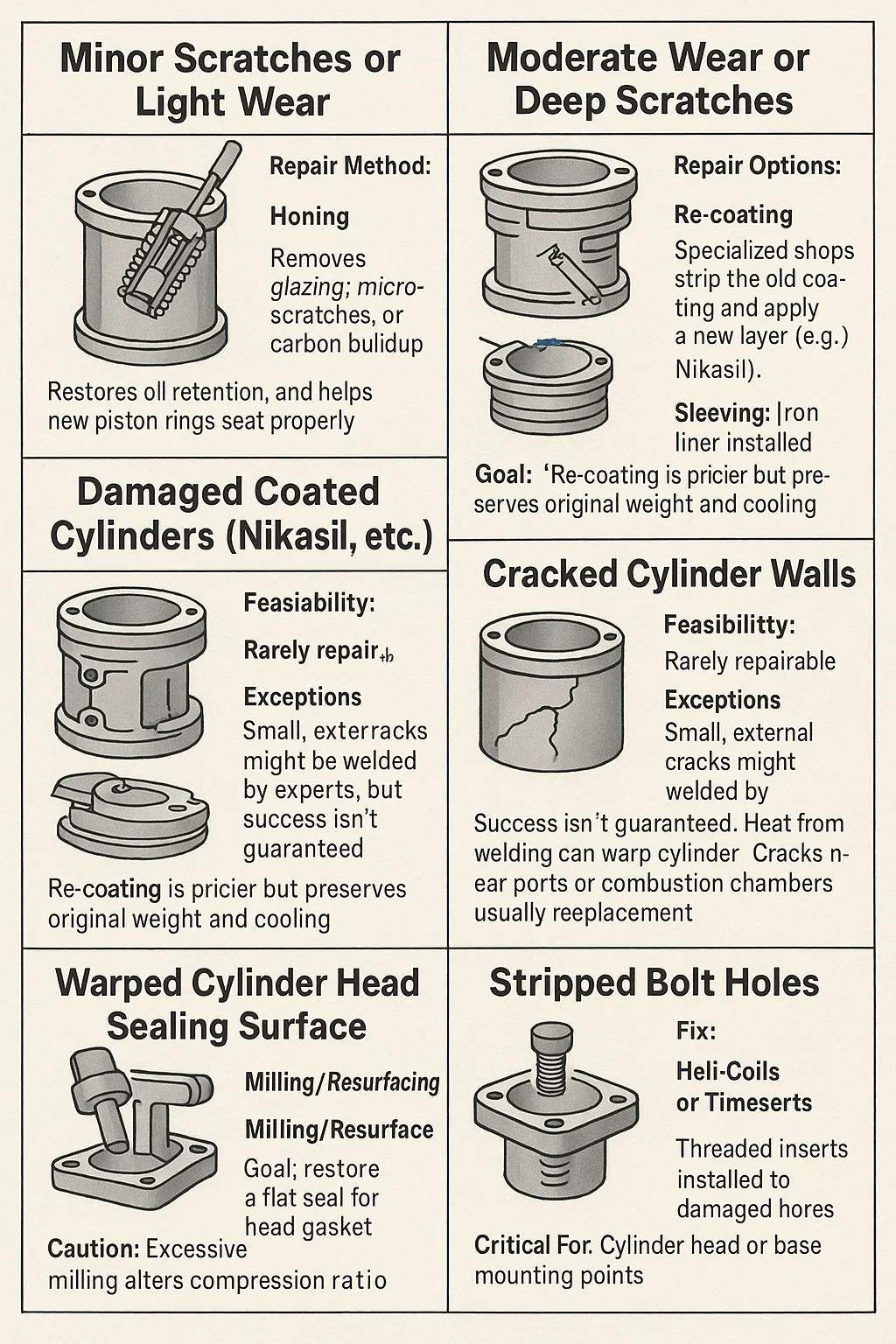

1. Minor Scratches or Light Wear

Repair Method: Honing

A honing tool lightly scrubs the cylinder walls to create a fresh crosshatch pattern.

Removes glazing, micro-scratches, or carbon buildup.

Purpose: Restores oil retention and helps new piston rings seat properly.

Limitations: Only works if the cylinder is still within factory diameter tolerances. Deep gouges require more aggressive fixes.

2. Moderate Wear or Deep Scratches

Repair Method: Overboring + Sleeving

Overboring: The cylinder is machined to a larger diameter to eliminate damage.

Sleeving: A new iron liner (sleeve) is pressed into the bored-out cylinder.

Result: Returns the cylinder to standard (or larger) bore size with a fresh surface.

Common Use: Classic bikes, heavily worn engines, or cases where original cylinders are rare/expensive.

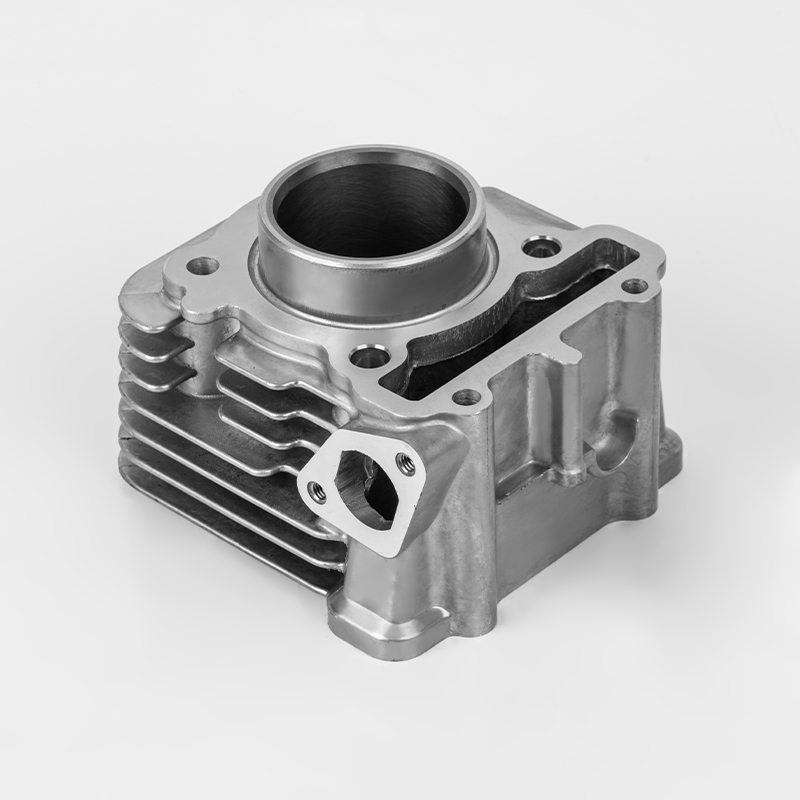

3. Damaged Coated Cylinders (Nikasil, etc.)

Repair Options:

Re-coating: Specialized shops strip the old coating and apply a new layer (e.g., Nikasil).

Sleeving: Iron liner installed after boring (common for DIY repairs).

Note: Re-coating is pricier but preserves the original weight and cooling.

4. Cracked Cylinder Walls

Feasibility: Rarely repairable.

Exceptions: Small, external cracks might be welded by experts, but success isn't guaranteed.

Risk: Heat from welding can warp the cylinder. Cracks near ports or combustion chambers usually mean replacement.

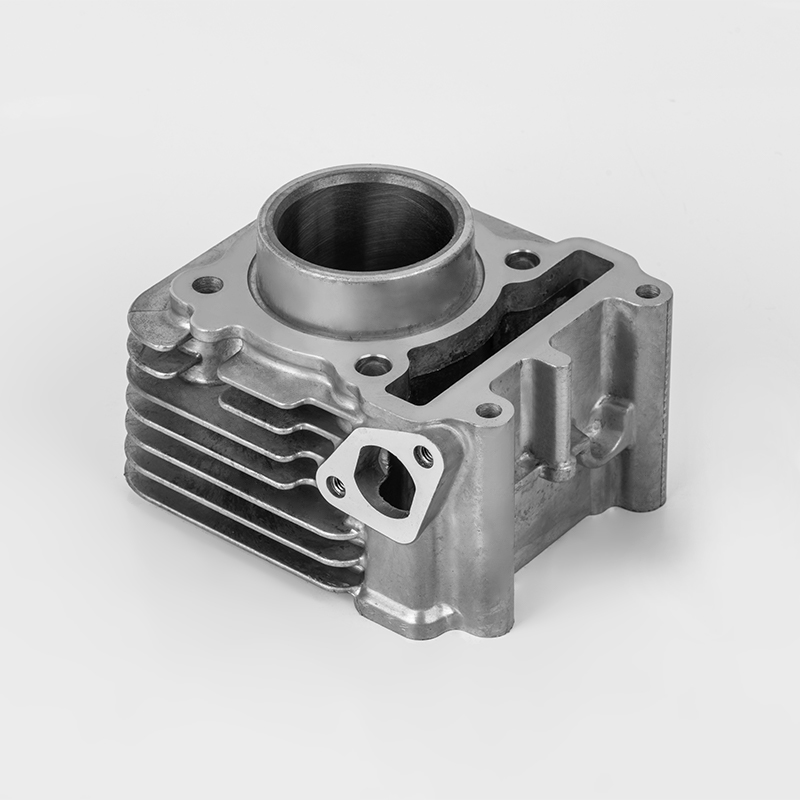

5. Warped Cylinder Head Sealing Surface

Repair Method: Milling/Resurfacing

Machine shop shaves a thin layer off the cylinder's top surface.

Goal: Restores a flat seal for the head gasket.

Caution: Excessive milling alters compression ratio and valve timing.

6. Stripped Bolt Holes

Fix: Heli-Coils or Timeserts

Threaded inserts installed to reinforce damaged holes.

Critical For: Cylinder head or base mounting points.

English

English Español

Español عربى

عربى