Here's where to get a motorcycle cylinder bored, with key considerations for choosing the right service:

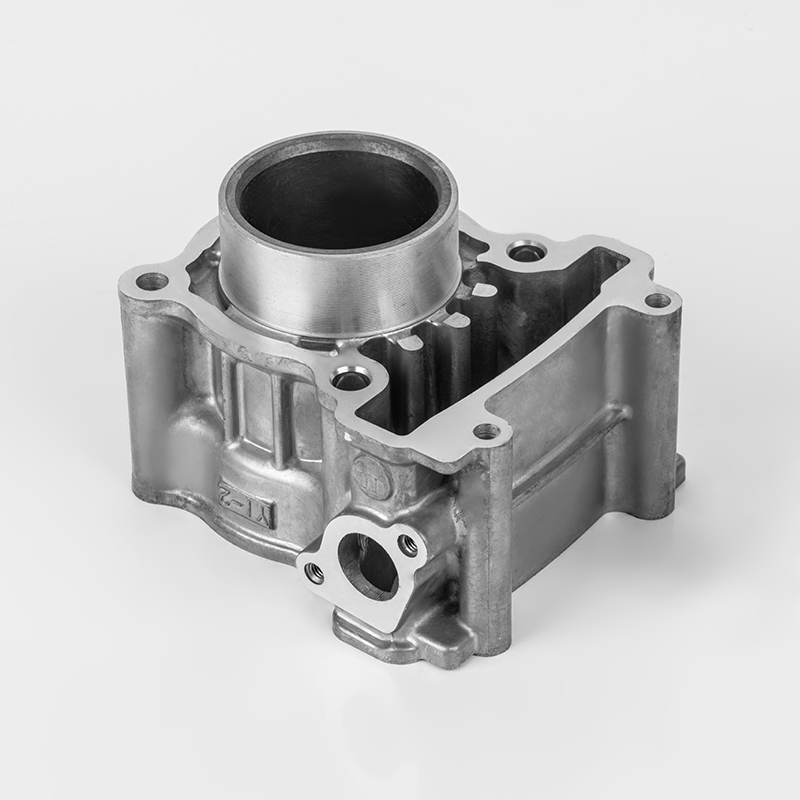

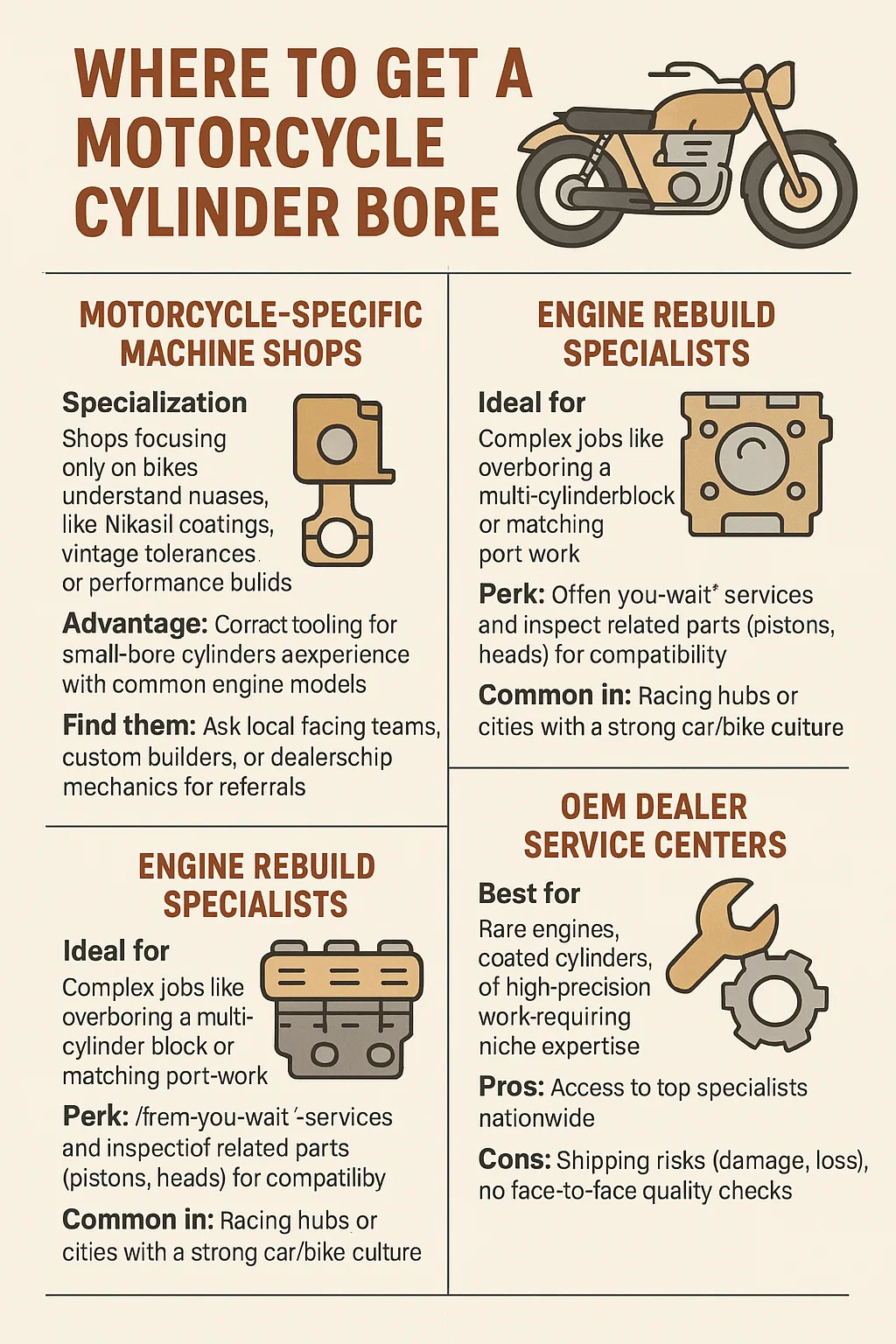

1. Motorcycle-Specific Machine Shops

Specialization: Shops focusing only on bikes understand nuances like Nikasil coatings, vintage tolerances, or performance builds.

Advantage: Correct tooling for small-bore cylinders and experience with common engine models.

Find them: Ask local racing teams, custom builders, or dealership mechanics for referrals.

2. Automotive Machine Shops (Selective Use)

When viable: For simple iron-lined cruiser/touring cylinders where motorcycle-specific shops are unavailable.

Risk: Many lack experience with aluminum blocks, plated bores, or tight tolerances needed for high-RPM engines.

Verify: Confirm they've handled motorcycle cylinders before and use precision boring bars.

3. Engine Rebuild Specialists

Ideal for: Complex jobs like overboring a multi-cylinder block or matching port work.

Perk: Often offer "while-you-wait" services and inspect related parts (pistons, heads) for compatibility.

Common in: Racing hubs or cities with a strong car/bike culture.

4. OEM Dealer Service Centers

When to use: For warranty work or if retaining factory specifications is critical.

Limitation: Typically replaces cylinders instead of boring them; costly for performance upgrades.

5. Postal/Mail-In Services

Best for: Rare engines, coated cylinders, or high-precision work requiring niche expertise.

Pros: Access to top specialists nationwide.

Cons: Shipping risks (damage, loss), no face-to-face quality checks.

English

English Español

Español عربى

عربى