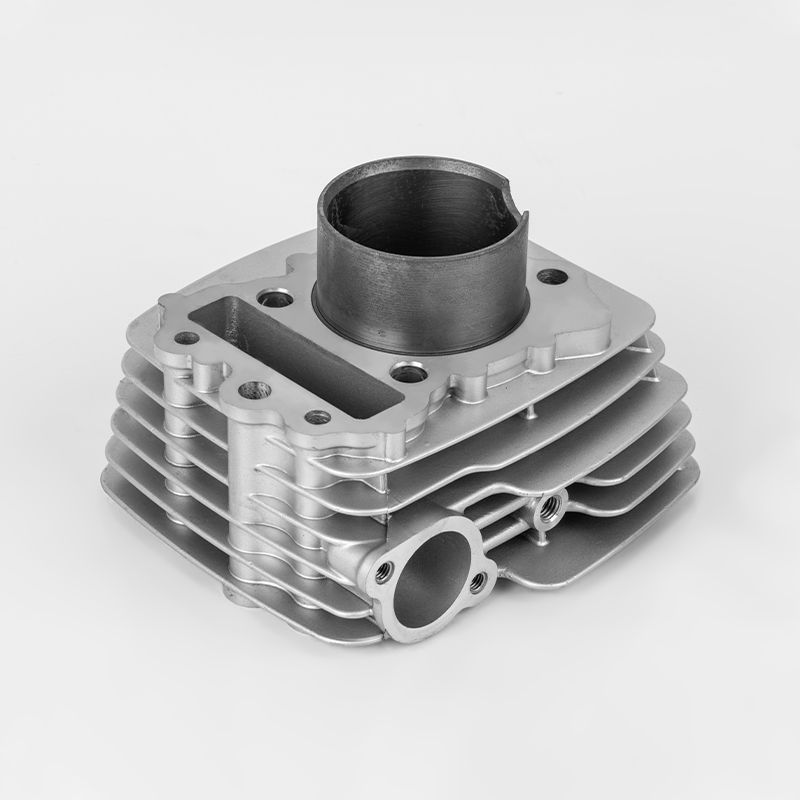

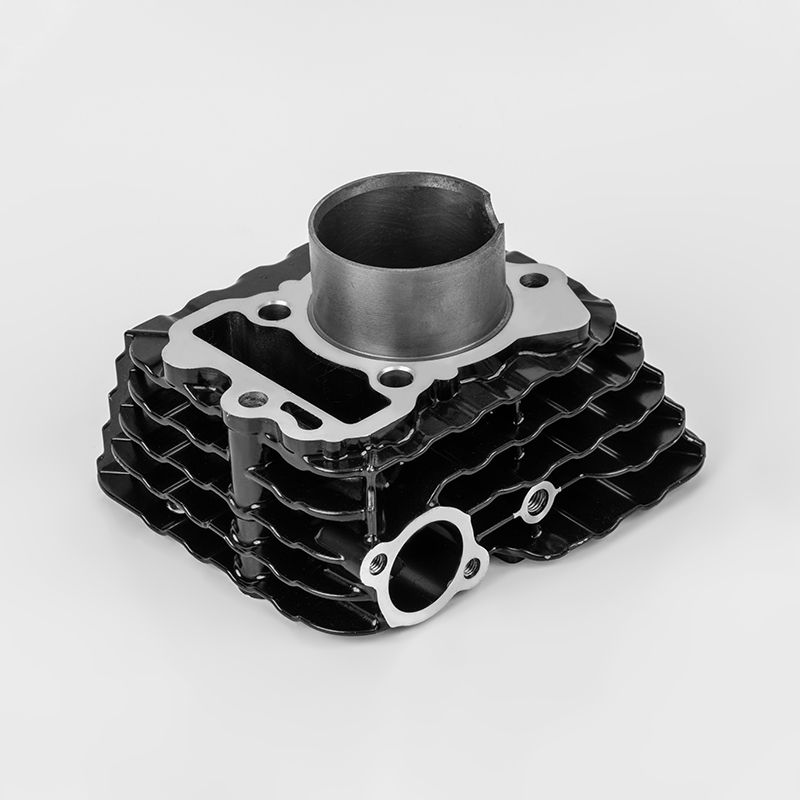

Q: What is the core material composition of the Baijiaji aluminum alloy motorcycle cylinder? How does this material affect the cylinder's overall performance and durability?

A: The Baijiaji series utilizes a high-purity aluminum alloy as its base material, typically incorporating alloying elements such as silicon, copper, and magnesium to achieve specific mechanical properties. This material composition is crucial in motorcycle engines because it significantly reduces the overall weight of the cylinder (over 30% lighter than traditional cast iron) while also improving heat transfer efficiency and reducing the risk of engine overheating. The aluminum alloy's microstructure is strengthened through a precision heat treatment process, ensuring high hardness and wear resistance, thereby extending the cylinder life to over 100,000 kilometers. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s R&D team customizes the alloy ratio and heat treatment parameters, optimizing the material's grain size distribution based on operating conditions, such as high-temperature or high-load environments, to match the engine requirements of different motorcycle models. This customized development not only enhances the Baijiaji series' adaptability but also ensures stable performance under extreme conditions, such as off-roading or long-distance riding.

Q: What are the key advantages of the Baijiaji series in improving motorcycle engine efficiency and power output? How do these advantages translate into real-world riding experience?

A: The core strength of the Baijiaji series lies in its lightweight design and optimized thermal management, which directly improves engine fuel efficiency and power response. The lightweight aluminum alloy cylinder (average weight reduction of 20-25%) reduces the engine's moment of inertia, enabling faster acceleration and shortening the 0-100 km/h time by approximately 0.5 seconds. Furthermore, its high thermal conductivity (approximately 200W/mK) quickly dissipates heat, preventing detonation and power loss, ensuring peak torque output during continuous high-speed operation. This translates into a significantly improved riding experience: for example, in urban traffic or mountain climbing conditions, engine noise is reduced by 15% and fuel consumption is reduced by 5-10%. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s R&D team developed customized cylinder inner wall coating technologies, such as micro-arc oxidation, by simulating real-world operating conditions (such as high temperature and humidity), to enhance surface hardness and corrosion resistance. This demand-driven design ensures the Baijiaji series delivers smooth and efficient power transmission in diverse riding scenarios, such as commuting and racing.

Q: How does Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. leverage its R&D capabilities to optimize the structural design of the Baijiaji aluminum alloy cylinder series? How does this address common engine issues?

A: Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd's R&D team utilizes advanced CAE (Computer-Aided Engineering) and FEA (Finite Element Analysis) tools to optimize the Baijiaji series' structure, focusing on addressing cylinder deformation, thermal expansion, and seal failure. For example, their multi-layer composite wall structure (including a reinforced inner liner and external cooling fins) effectively dissipates thermal stress and reduces the risk of cylinder deformation at high temperatures (deformation rate less than 0.1mm). This design also incorporates precise machining tolerances (e.g., ±0.01mm) to ensure a perfect fit between the piston rings and the cylinder wall, eliminating blowby and oil consumption issues. During the development process, the team adjusts cylinder geometry (such as diameter and stroke ratio) to match the engine's compression ratio based on operating conditions (e.g., high-altitude, low-oxygen environments). Through this demand-driven R&D approach, the Baijiaji series boasts over 99% reliability in combating common engine failures (such as cylinder scuffing and power loss), while also reducing maintenance frequency.

Q: Under what specific operating conditions does the Baijiaji series perform best? How does Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd develop its products to ensure they are suitable for these challenging environments?

A: The Baijiaji series excels in high-temperature, high-humidity, and high-vibration conditions, such as those encountered during tropical cycling, desert exploration, or heavy motorcycle hauling. In these environments, the aluminum alloy cylinder's resistance to thermal fatigue (up to 300°C) and corrosion (500-hour salt spray testing) plays a key role in preventing engine performance degradation. Specifically, thermal deformation of the cylinder is minimized during sustained high-speed operation, ensuring airtightness and consistent power. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s R&D team develops customized solutions through field testing and operating simulations (such as those simulating the high-temperature and high-humidity conditions found in Southeast Asia). For example, surface treatments such as anodizing or DLC coating are optimized to enhance wear resistance and rust prevention. The team also incorporated materials science expertise to tailor the alloy composition to specific humidity levels (e.g., relative humidity above 80%), ensuring the Baijiaji series maintains a low failure rate and long lifespan even under demanding conditions (such as riding in the rainy season).

Q: What are the material science differences of the Baijiaji aluminum alloy series compared to traditional cast iron or steel cylinders? How does this impact the motorcycle's overall design?

A: The Baijiaji series' uniqueness lies in its aluminum alloy's low density and high specific strength. Its density is only one-third that of cast iron (approximately 2.7g/cm³), yet its tensile strength exceeds 300MPa. This achieves a balance of lightweight and strength, reducing the overall engine weight and optimizing the motorcycle's center of gravity distribution and handling. In contrast, cast iron cylinders, while wear-resistant, are heavy and prone to increased engine vibration. The Baijiaji series utilizes nano-grain strengthening technology to increase the fatigue limit (over 10^7 cycles), reducing the risk of cracking. This design impacts the motorcycle's overall architecture: for example, lightweight cylinders allow for a more compact engine, freeing up more space in the frame, improving steering agility and fuel efficiency. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s R&D team built upon this foundation, developing customized alloy formulations (such as the addition of rare earth elements) to enhance the material's toughness and thermal stability, tailored to operating conditions (such as the high-G forces of racing motorcycles). This innovation ensures seamless integration and enhanced performance across a wide range of motorcycle types, from cruisers to sports bikes.

Q: How does the Baijiaji series, supported by Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd's R&D, contribute to improved engine life and sustainability?

A: The Baijiaji series significantly extends engine life and reduces environmental impact through material optimization and surface engineering. For example, its low-friction design (reducing friction losses by 20%) reduces piston wear, and combined with precision heat treatment, it achieves a cylinder life of over 150,000 kilometers. Furthermore, the aluminum alloy's recyclability exceeds 95%, reducing waste pollution. The R&D team at Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. plays a key role in this effort. They leverage operating condition analysis tools (such as big data-based riding mode simulations) to develop environmentally friendly coatings (such as chromium-free passivation) to meet green manufacturing standards. The team also optimizes cylinder combustion efficiency based on specific needs (such as low-emission requirements for urban commuting), reducing unburned hydrocarbon emissions to support motorcycles meeting Euro V and China VI standards. This R&D-driven iteration ensures that the Baijiaji series not only improves product reliability but also drives the industry towards low-carbon development.

Q: How does Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd's R&D process integrate user feedback and operating condition data to continuously improve the performance of the Baijiaji series?

A: Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd's R&D team utilizes a closed-loop feedback mechanism, collecting global user riding data (such as engine temperature logs and fault reports) and combining it with operating condition simulation laboratory testing to continuously optimize the Baijiaji series. For example, by analyzing cylinder stress distribution under high-load conditions, the team developed a dynamic cooling channel design to enhance heat exchange efficiency. In response to user feedback regarding vibration issues during mountain riding, the team adjusted the material damping properties to reduce the risk of resonance. This demand-driven process involves multidisciplinary collaboration (such as thermodynamics and materials engineering), ensuring that each product iteration (such as upgrading the micropore structure of the cylinder wall) targets practical pain points. Ultimately, with the support of Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd, the Baijiaji series achieves continuous performance evolution, meeting the needs of all scenarios, from daily commuting to professional racing.

English

English Español

Español عربى

عربى