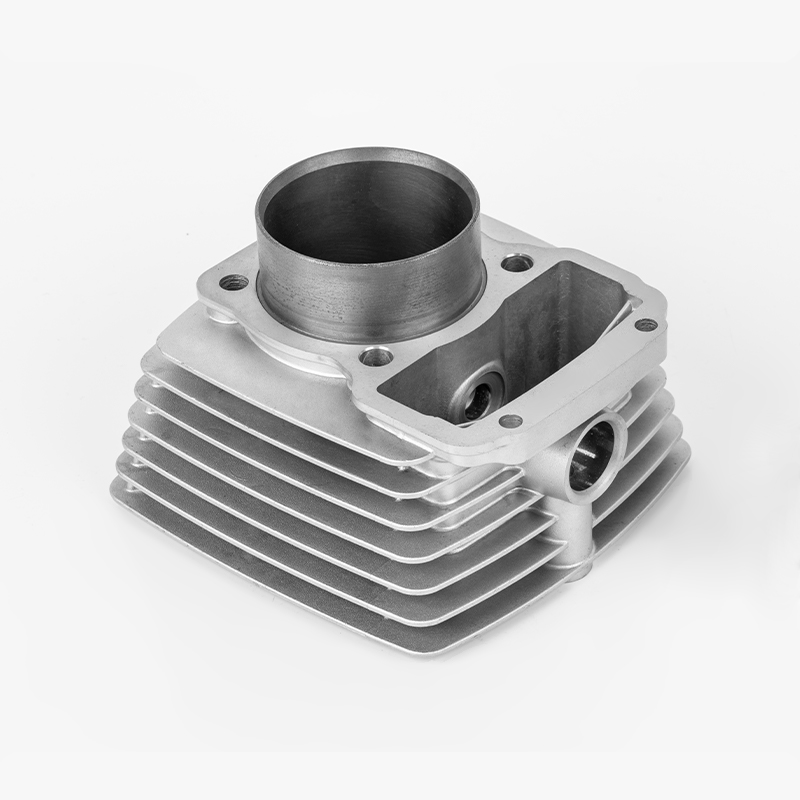

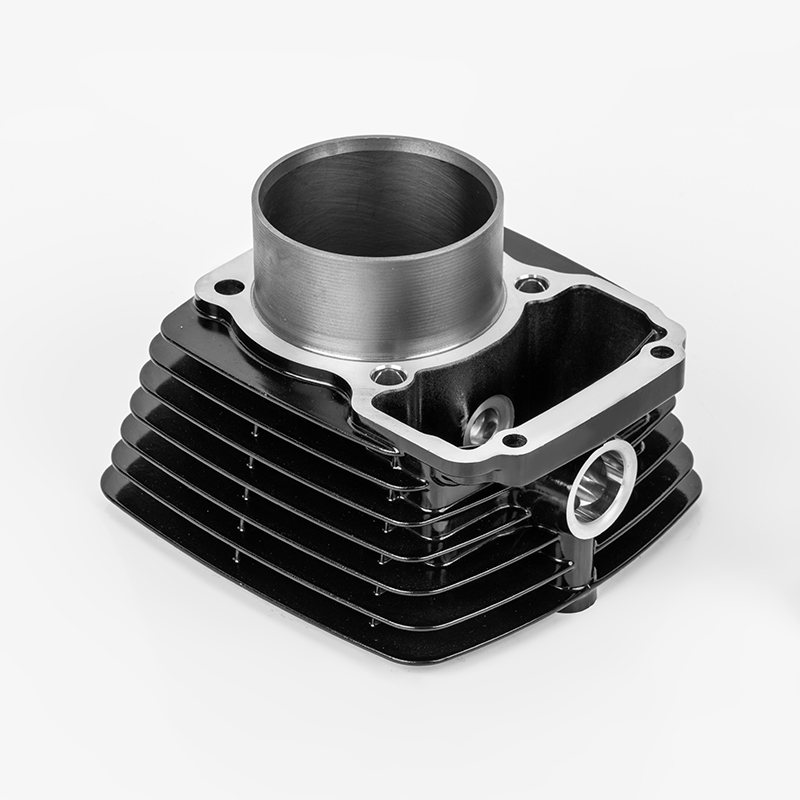

In the world of motorcycle engineering, Honda's aluminum alloy motorcycle cylinder series has long been a core component of high-performance engines.

1. Q: What is the basic definition and function of the Honda aluminum alloy motorcycle cylinder series? How does it differ from traditional cylinders?

A: The Honda aluminum alloy motorcycle cylinder specifically refers to cylinder components in Honda motorcycle engines made of aluminum alloy. They primarily accommodate piston movement, control fuel combustion, and dissipate heat. Compared to traditional cast iron cylinders, the primary difference lies in the material choice: aluminum alloy offers significant lightweighting advantages (typically reducing engine weight by 20%-30%), while also possessing excellent thermal conductivity, allowing combustion heat to dissipate more quickly and preventing engine overheating. This directly improves the motorcycle's acceleration performance and fuel efficiency. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. integrates the entire design, casting, and finishing process to ensure the precision of the aluminum alloy cylinder's internal structure, maximizing Honda's design philosophy—for example, reducing friction losses and extending engine life.

2. Q: Why did Honda choose aluminum alloy as the cylinder material? What key advantages does this material offer in motorcycle applications?

A: Honda's core reason for choosing aluminum alloy stems from its comprehensive performance advantages. First, aluminum alloy's low density (approximately 2.7g/cm³) significantly reduces overall engine weight, which is crucial for motorcycles—lightweight design directly impacts handling agility and high-speed stability. Second, aluminum alloy's thermal conductivity is much higher than cast iron (approximately 150-200 W/mK), effectively dissipating heat and preventing hot spots, ensuring reliable engine operation under extreme conditions (such as long-distance riding or high-temperature environments). Furthermore, aluminum alloy can be heat-treated to enhance its hardness and wear resistance, and surface coatings (such as nickel-silicon carbide layers) can enhance its corrosion and wear resistance. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. strictly controls the aluminum alloy ratio and casting process during production to ensure material uniformity, thereby achieving the long-term durability required by Honda—for example, reducing the risk of cylinder wall deformation and preventing piston seizure.

3. Q: In a motorcycle engine, how do aluminum alloy cylinders affect overall performance and the user experience? What's unique about Honda's design?

A: Aluminum alloy cylinders play a critical role in engine performance, directly impacting horsepower output, responsiveness, and reliability. As the piston moves at high speed within the cylinder, the lightweight nature of aluminum alloy reduces inertial resistance, enabling the engine to reach peak torque sooner (typically between 3,000 and 8,000 RPM), improving acceleration response—particularly critical for sportbikes. Furthermore, efficient heat dissipation prevents power loss (thermal efficiency can be improved by 5%-10%), ensuring more complete fuel combustion and reducing emissions and fuel consumption (for example, saving fuel in urban riding mode). Honda emphasizes "balance" in its design by optimizing cylinder wall thickness and cooling channel layout (for example, using computer-simulated fluid dynamics) to avoid localized overheating and vibration and noise. As a production partner, Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. leverages its comprehensive process capabilities to implement rigorous quality control, ensuring each cylinder meets Honda's performance standards. For example, non-destructive testing verifies internal defects, ensuring a smooth, quiet ride.

4. Q: What are the core processes involved in producing Honda's aluminum alloy cylinders? How are precision and consistency ensured throughout these processes?

A: The key processes in aluminum alloy cylinder production include material preparation, precision casting, machining, surface treatment, and final testing. First, the aluminum alloy ingot is melted and alloyed (often with silicon and copper added to optimize strength). Then, the cylinder blank is formed using low-pressure or gravity casting—this ensures internal porosity is below 0.5% to prevent future leaks. Next, CNC machine tools perform finishing (such as drilling and boring) with micron-level tolerances to ensure precise piston clearance (standard: 0.02-0.05mm). Surface treatment involves anodizing or thermal spraying to enhance wear and corrosion resistance. Finally, performance testing includes pressure leak checks and high- and low-temperature cycling tests. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. demonstrates expertise in this area, capable of independently completing all processes (from raw materials to finished product). Automated systems and rigorous QC protocols (such as sampling statistical process control) ensure batch consistency. This not only shortens production cycle times (typical delivery times are 15% faster than the industry average) but also meets Honda's stringent requirements for dimensional accuracy and surface finish (for example, Ra values below 0.8μm).

5. Q: What role does Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. play in producing Honda's aluminum alloy cylinder series? How does its "full-process production capabilities" translate into tangible value?

A: As a dedicated manufacturing partner, Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. provides an end-to-end solution to support the scaled-up production of Honda's aluminum alloy cylinder series. These full-process capabilities encompass design collaboration, prototyping, serial manufacturing, and logistics management, ensuring a seamless transition from concept to finished product. This eliminates the risk of delays associated with outsourcing and enhances quality traceability (for example, each cylinder can be traced back to its casting batch). The specific value is reflected in two aspects: first, product quality assurance. The company uses advanced equipment (such as spectrometers) to monitor material purity and process parameters, reducing defect rates (targeting less than 0.1%). Second, production time optimization. By integrating resources, the company can compress standard production cycles to within 30 days, easily handling urgent orders. This capability makes Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. a reliable link in Honda's supply chain, helping to improve the overall reliability of aluminum alloy cylinders (such as extending warranty periods) while also complying with Industry 4.0 standards (such as optimizing efficiency through real-time data monitoring).

6. Q: What are the long-term benefits of choosing Honda's aluminum alloy cylinder series for motorcycle users and repairers? How does Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s involvement impact the aftermarket?

A: Users and repairers who choose Honda's aluminum alloy cylinder series enjoy several long-term benefits: extended engine life (typically exceeding 100,000 kilometers) thanks to the material's fatigue resistance; reduced maintenance costs due to efficient heat dissipation that reduces oil degradation (oil change intervals can be extended by 20%); and consistent performance, avoiding power loss due to cylinder wear. In the aftermarket, Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s comprehensive production capabilities ensure a stable supply of spare parts with consistent quality. The company can quickly respond to demand fluctuations (such as peak season orders) and provide OEM-grade replacement parts, minimizing customer downtime. Furthermore, rigorous production controls (such as 100% factory testing) ensure cylinder compatibility across a wide range of Honda models, allowing repairers to easily install without requiring additional adjustments. This reinforces Honda's reputation in the market for high performance and low failure rates. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s contributions have made cylinders a trusted core component.

English

English Español

Español عربى

عربى