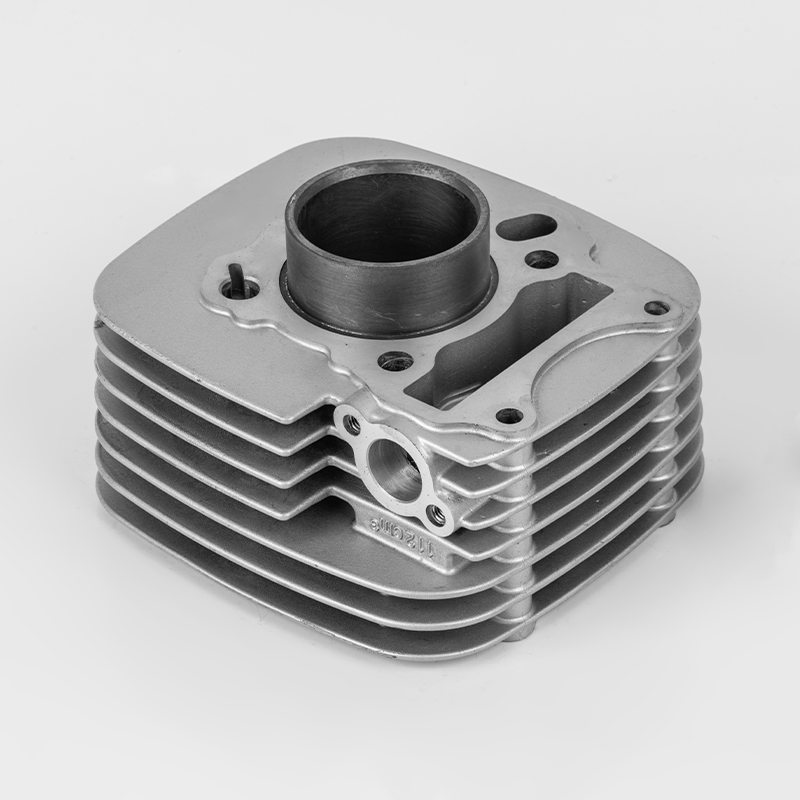

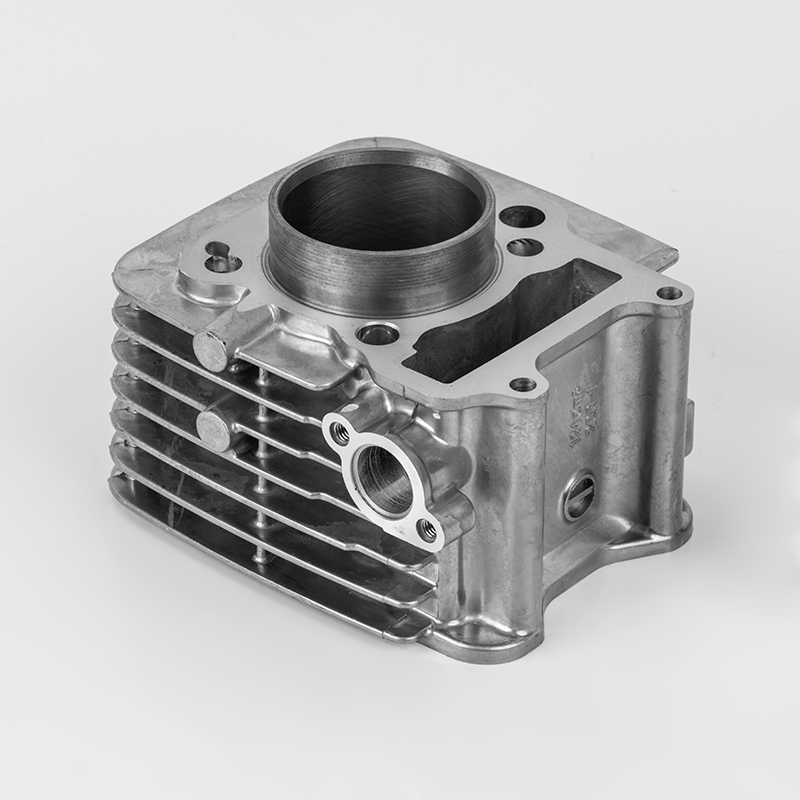

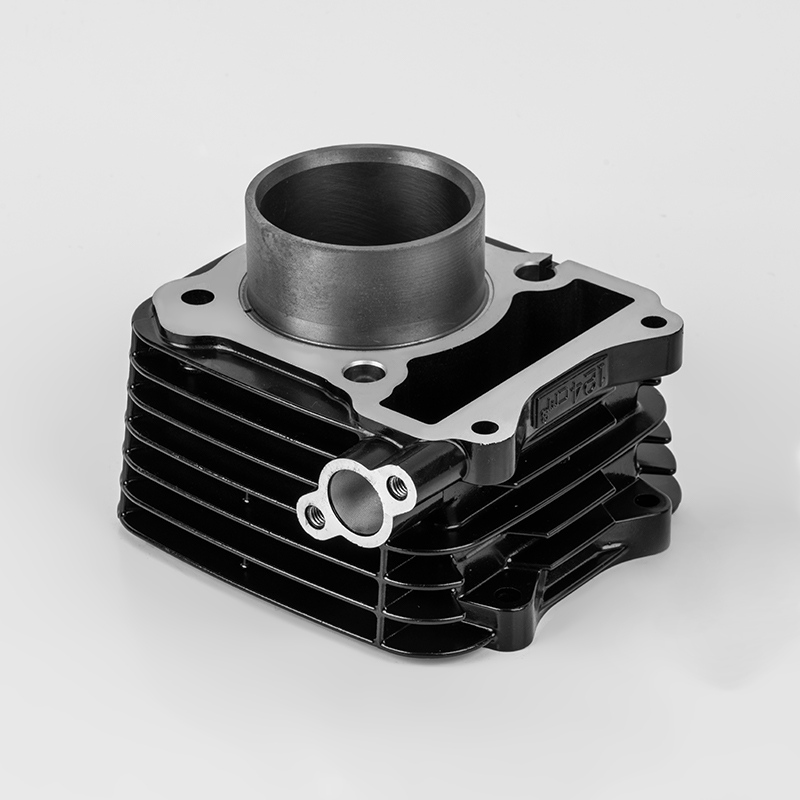

In the motorcycle industry, Suzuki aluminum alloy motorcycle cylinder represents the perfect combination of lightweight and high performance. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd., a professional manufacturer with a diverse range of casting processes (including die casting, low-pressure casting, and cast iron casting), is able to provide strong R&D and production support for these advanced components.

Question 1: What is the role of aluminum alloy cylinders in motorcycle engines? Why does Suzuki place particular emphasis on aluminum alloy materials?

Answer: Aluminum alloy cylinders are core components of motorcycle engines, primarily responsible for accommodating piston movement and maintaining sealing under high-temperature and high-pressure environments. Suzuki chose aluminum alloy primarily for its unique physical properties: aluminum alloy offers exceptional lightweight advantages (with a density only half that of steel), significantly reducing overall engine weight and improving vehicle acceleration and fuel efficiency. Furthermore, aluminum alloy's high thermal conductivity helps dissipate combustion heat quickly, preventing overheating and deformation in the engine, and extending its service life. In industrial applications, aluminum alloy also exhibits excellent plasticity, facilitating the manufacture of complex structures through precision casting. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s diverse casting capabilities, such as die-casting, enable efficient production of these components, maximizing material properties. Die-casting technology achieves high-precision molding and reduces porosity defects, which aligns perfectly with Suzuki pursuit of high reliability. Overall, aluminum alloy cylinders represent a trend in modern motorcycle design, balancing performance and economy.

Question 2: What is unique about Suzuki aluminum alloy cylinder manufacturing process? How is durability and precision ensured?

Answer: Suzuki aluminum alloy cylinder manufacturing process focuses on precision casting, emphasizing the use of high-pressure or low-pressure casting techniques to optimize microstructure and surface quality. For example, die-casting injects molten aluminum alloy into a mold at high pressure, enabling the creation of thin-walled, high-strength cylinder blocks and minimizing material waste. Low-pressure casting, on the other hand, is more suitable for complex geometries, ensuring uniform internal stress distribution and preventing cracking. These processes are unique in their stringent heat treatment requirements: post-casting, an age-hardening treatment is required to enhance the aluminum alloy's hardness and wear resistance. Test data shows that properly treated cylinders can extend cylinder life by over 30%. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s low-pressure die casting and cast iron casting processes are perfectly suited to these needs. The company can flexibly select process parameters based on different cylinder designs (such as cooling channel geometry and cylinder bore size) and control the alloy solidification process to avoid porosity or shrinkage defects. Combined with Suzuki stringent quality control, this integrated process ensures cylinder geometric precision (tolerances are controlled to the micron level) and high-temperature stability, meeting the long-term durability requirements under high-speed riding conditions.

Question 3: What performance advantages do aluminum alloy cylinders have over traditional cast iron cylinders? How do these advantages affect the overall performance of the motorcycle?

A: Aluminum alloy cylinders offer significant advantages over traditional cast iron cylinders in three key performance dimensions: First, they are lighter (aluminum alloy density is approximately 2.7g/cm³ vs. cast iron 7.8g/cm³), which directly reduces the engine's rotational inertia and improves acceleration response and handling sensitivity. Second, they offer more efficient heat dissipation. Aluminum alloy has a thermal conductivity of up to 200W/mK, which transfers combustion heat to the cooling system more quickly, preventing detonation or power loss. This is particularly critical in Suzuki high-speed engines. Third, they offer a lower coefficient of friction. The aluminum alloy surface can be made smooth through coating, reducing piston ring wear and extending maintenance intervals. These advantages combine to contribute to the motorcycle's overall performance: lightweighting optimizes the power-to-weight ratio, giving the vehicle greater explosive power when starting and climbing. Efficient heat dissipation ensures stable engine output under extreme conditions, reducing power attenuation. The low-friction design reduces fuel consumption and emissions, meeting modern environmental standards. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s casting processes, such as die casting, can precisely achieve these properties. For example, low-pressure casting controls alloy fluidity, producing cylinders with uniform internal structures, thereby amplifying the performance gains of aluminum alloys.

Question 4: Why is the choice of casting process so critical when manufacturing aluminum alloy cylinders? How does Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s diverse processes adapt to the Suzuki series?

Answer: The choice of casting process determines the final quality and cost-effectiveness of aluminum alloy cylinders, as the process directly impacts material density, defect control, and production efficiency. Die casting is suitable for large-scale production, offering high speed and low cost, but the risk of hot cracking must be controlled. Low-pressure casting provides more uniform filling and fewer slag inclusions, making it suitable for high-precision parts. Although cast iron casting is primarily used for other materials, its process experience can optimize mold design. For the Suzuki series, the process selection must balance lightweighting and strength. For example, die casting can quickly produce thin-walled cylinders, but subsequent heat treatment is required to strengthen the grain boundary structure. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s diverse process technologies (die casting, low-pressure casting, etc.) are perfectly suited to this need: the company can switch between different processing modes based on the specific specifications of Suzuki cylinders, such as dimensional variations or complex shapes. For example, die casting allows for efficient production of small cylinders (bore <100mm), while low-pressure casting ensures smooth transitions in the cooling channels for high-performance models. This flexibility not only improves production adaptability but also reduces overall costs by reducing scrap, demonstrating the collaborative evolution of process and product design.

Question 5: How does Suzuki aluminum alloy cylinder series address the environmental and efficiency demands of modern motorcycles? What role does Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s processes play in this effort?

Answer: Suzuki aluminum alloy cylinder series directly addresses environmental and efficiency challenges, reducing its carbon footprint through material innovation. Aluminum alloy has a high recyclability rate (recycling rate >90%), and its lightweight design reduces fuel consumption, resulting in a 5-10% improvement in mileage in real-world tests. Furthermore, optimized heat dissipation reduces nitrogen oxide emissions, meeting global standards such as Euro V. At the process level, precision casting ensures a compact cylinder design, integrates more features (such as built-in sensor slots), and enhances engine intelligence. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s role is to provide sustainable manufacturing solutions. The company utilizes low-pressure casting and die-casting processes to minimize energy consumption and material waste (for example, die-casting's rapid prototyping reduces processing steps). It also leverages its R&D capabilities to develop novel aluminum alloy formulations (such as adding silicon to enhance hardness). This not only helps Suzuki meet increasingly stringent regulations but also promotes the industry's transition to green manufacturing. The company's process scalability allows for rapid iteration to adapt to future e-motorcycle cylinder requirements.

Question 6: Looking ahead, what technological evolutions are likely to occur in Suzuki aluminum alloy cylinder series? How will Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s processes contribute to innovation?

A: Future technological evolution will focus on material composites and intelligent integration. For example, aluminum alloy cylinders may incorporate nano-coatings or ceramic reinforcements to further increase wear resistance and temperature limits. Furthermore, integrated sensors can monitor cylinder pressure in real time to enable predictive maintenance. These innovations require more precise casting processes to control microstructures. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd.'s diverse process expertise, including cast iron casting experience, can accelerate this type of R&D. Through low-pressure casting, the company can test new alloy ratios and simulate complex load scenarios to ensure product reliability under extreme conditions. Combined with Suzuki engineering expertise, this collaboration will drive the evolution of cylinders towards lightweight, efficient, and intelligent design.

English

English Español

Español عربى

عربى