Question: What is the basic principle of Yamaha motorcycle cylinder?

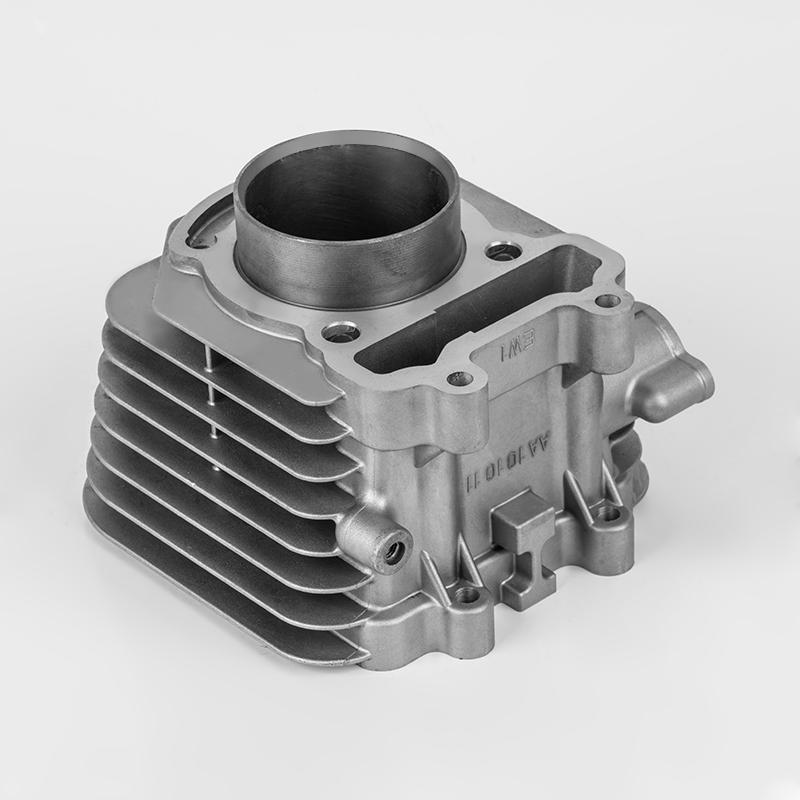

Yamaha motorcycle cylinders are one of the core components of the engine, responsible for converting fuel and air mixtures into mechanical energy.

The cylinder contains a piston and a combustion chamber. When the mixture is ignited, the generated high-temperature and high-pressure gas pushes the piston to move, thereby driving the crankshaft to rotate, providing power to the motorcycle. This process relies on precise engineering design and materials science to ensure efficient energy conversion.

In the research and development, Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. cooperates with international research institutions to explore optimization solutions for cylinder materials, aiming to improve its durability and thermal efficiency, so as to respond to market demand and develop more reliable solutions.

Question: What key role does Yamaha cylinder play in motorcycle performance?

Yamaha cylinders directly affect the overall performance of the motorcycle, involving power output, stability and fuel economy.

The design of the cylinder determines the compression ratio and combustion efficiency of the engine, which is related to the acceleration capability and maximum speed of the motorcycle. The optimized cylinder structure can reduce energy loss, improve power response, and control emissions to ensure environmental standards.

The cooling system of the cylinder is crucial, and Yamaha uses advanced air-cooling or liquid-cooling technology to prevent performance degradation caused by overheating. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. has cooperated with international partners to develop new cooling solutions to help iterate products quickly and adapt to the market's demand for high-performance motorcycles.

Question: What are the innovative characteristics of Yamaha in cylinder technology?

Yamaha is known for its innovation in the field of cylinder technology, focusing on lightweight, durability and sustainability.

The lightweight design is the core advantage of the Yamaha cylinder, using high-strength alloy materials to reduce the overall weight while maintaining structural rigidity, which improves the handling and fuel efficiency of the motorcycle. Innovations also include surface treatment processes such as plating technology to reduce friction loss and extend service life.

The R&D team of Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. focuses on the development of new technologies and cooperates with international research institutions to promote materials science, such as exploring the application of recycled materials in cylinders, achieving rapid response to market changes and launching more environmentally friendly innovative products.

Question: What should be paid attention to when maintaining and optimizing cylinder technology?

Maintaining Yamaha motorcycle cylinders requires attention to daily maintenance and professional adjustment to ensure long-term reliable operation.

Regular cleaning of carbon deposits inside the cylinder is key, which prevents power drops due to insufficient combustion. Use special cleaners and tools for maintenance to prevent impurities from entering the combustion chamber and affecting performance. At the same time, check seals such as piston rings to ensure good airtightness and reduce oil leakage or power loss.

Optimizing cylinder performance involves professional adjustments, such as adjusting the timing of ignition or the ratio of the mixture. Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. develops easy-to-maintenance solutions through technological innovation, and cooperates with international partners to simplify processes, helping users quickly adapt to maintenance needs and enhance product competitiveness.

Question: What are the future development trends of cylinder technology?

Cylinder technology is developing towards intelligence, environmental protection and efficiency to meet the global motorcycle evolution needs.

Intelligent integration is the focus of the future. For example, sensors are integrated into the cylinder to monitor combustion status and temperature in real time, and optimize performance through data feedback. This helps to achieve adaptive control, improve driving experience and safety. Environmental trends promote the use of bio-based materials or low-emission designs, reducing carbon footprint and in line with the Sustainable Development Goals.

Ningbo Daxie Development Tianshan Cylinder Block Co., Ltd. actively participates in this change, cooperates with international research institutions to develop cutting-edge technologies, quickly respond to the market's demand for green travel, promote new product development, and ensure that cylinder technology is always at the forefront of the industry.

English

English Español

Español عربى

عربى