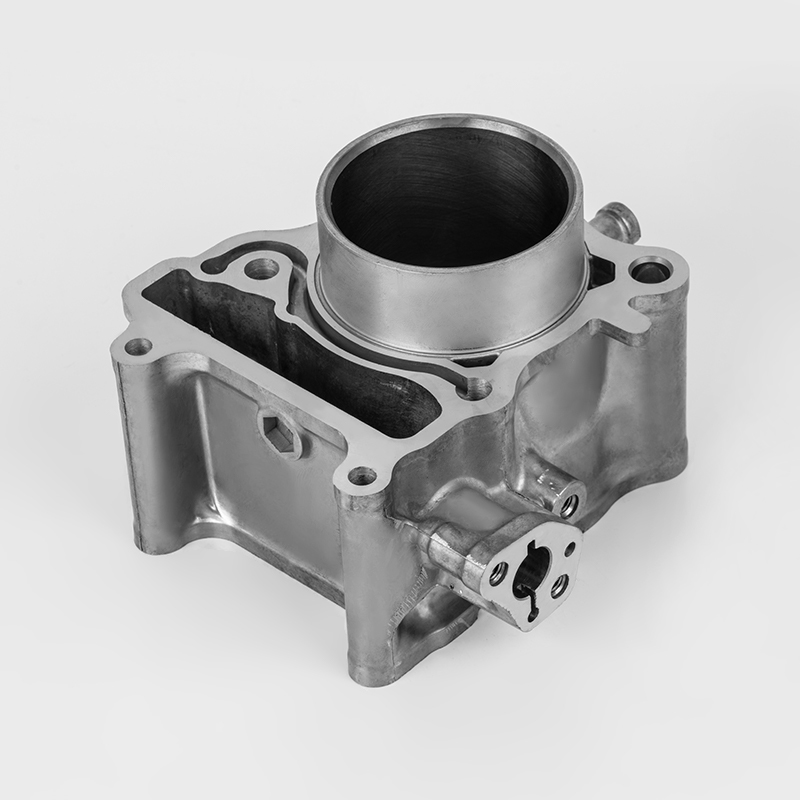

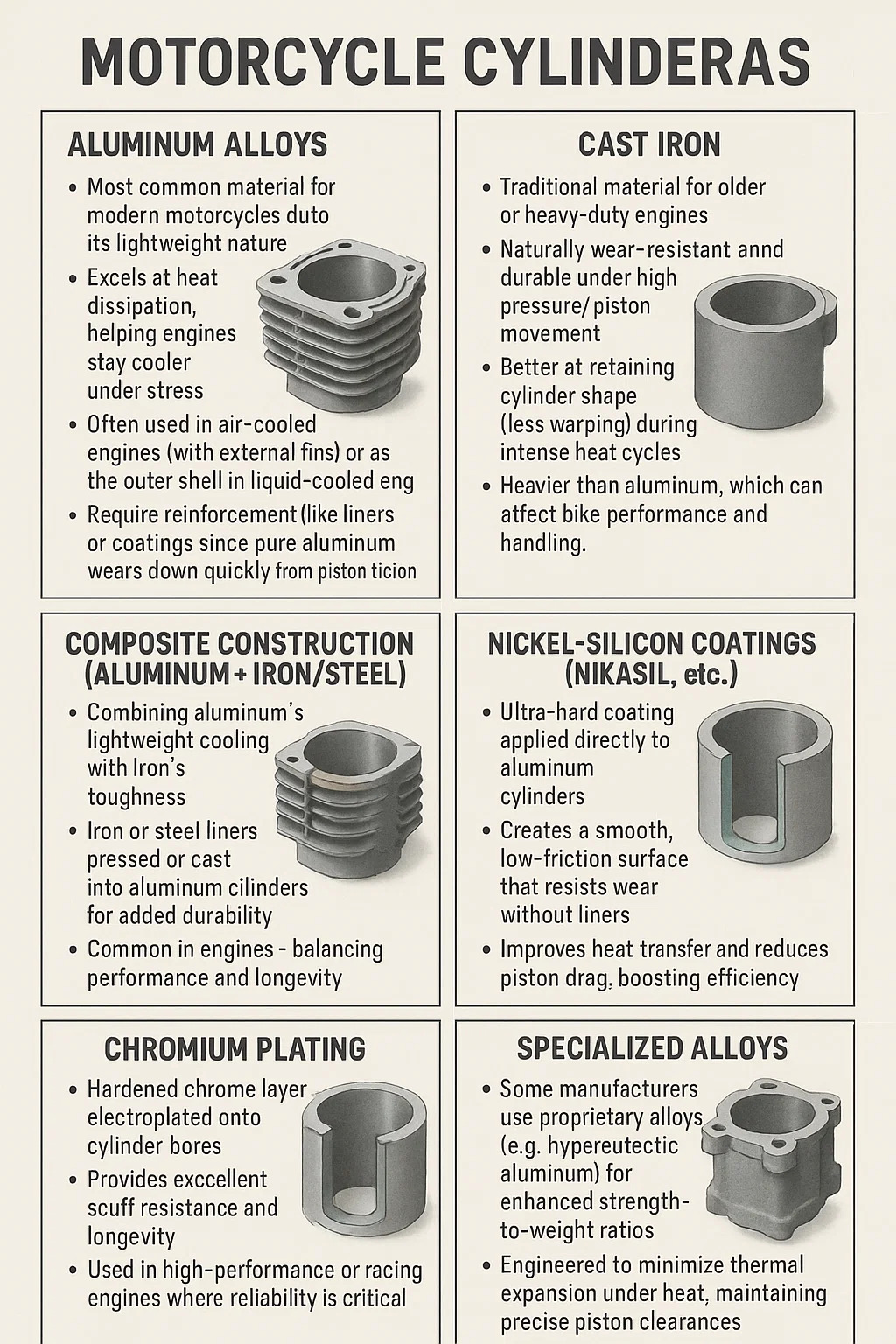

Motorcycle cylinders are primarily made from metals chosen for strength, heat tolerance, and durability. Here’s a detailed breakdown of common materials and their characteristics:

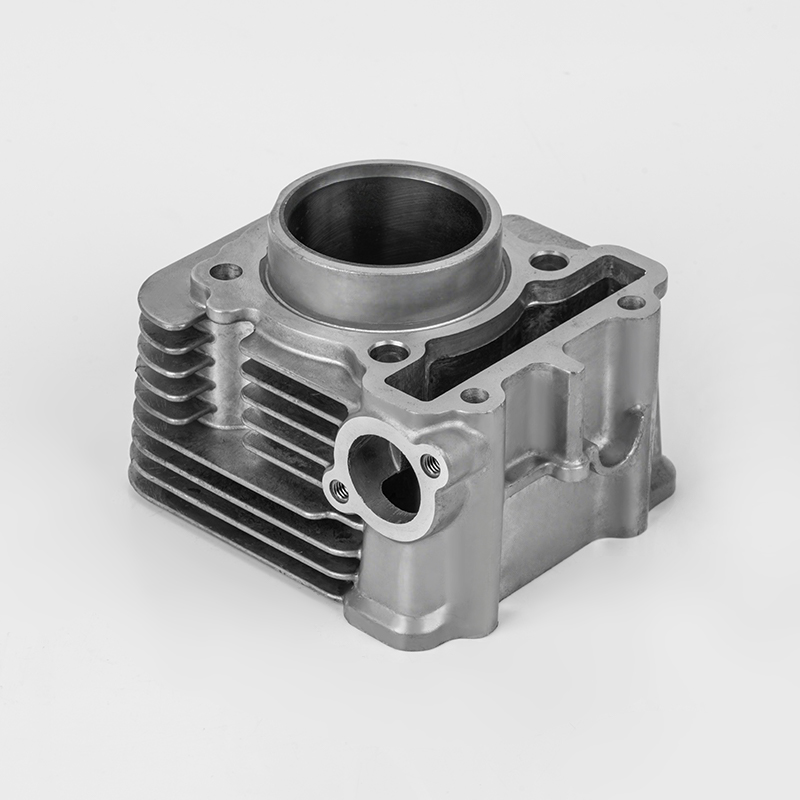

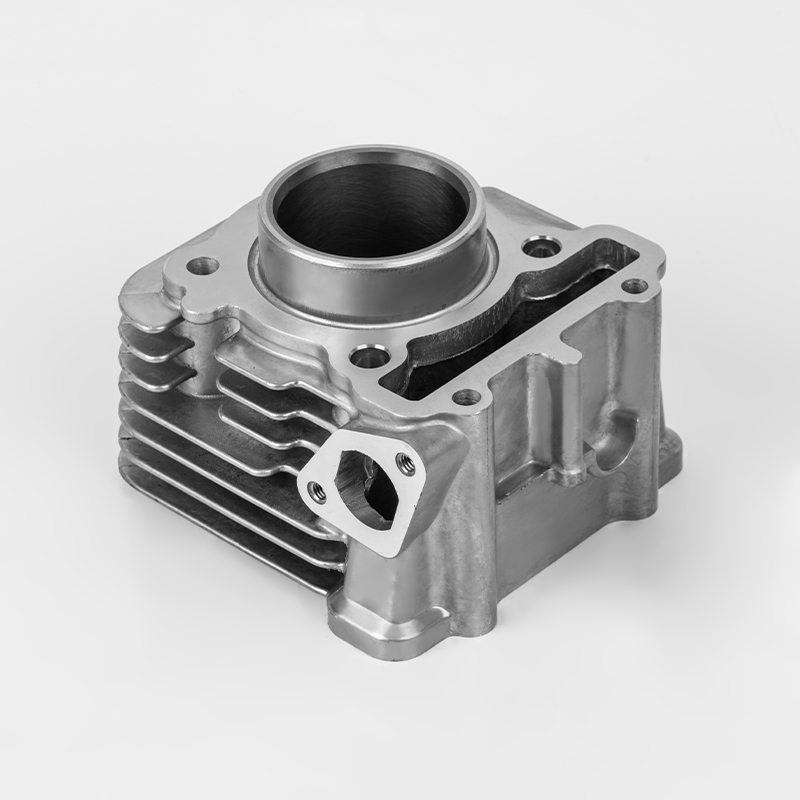

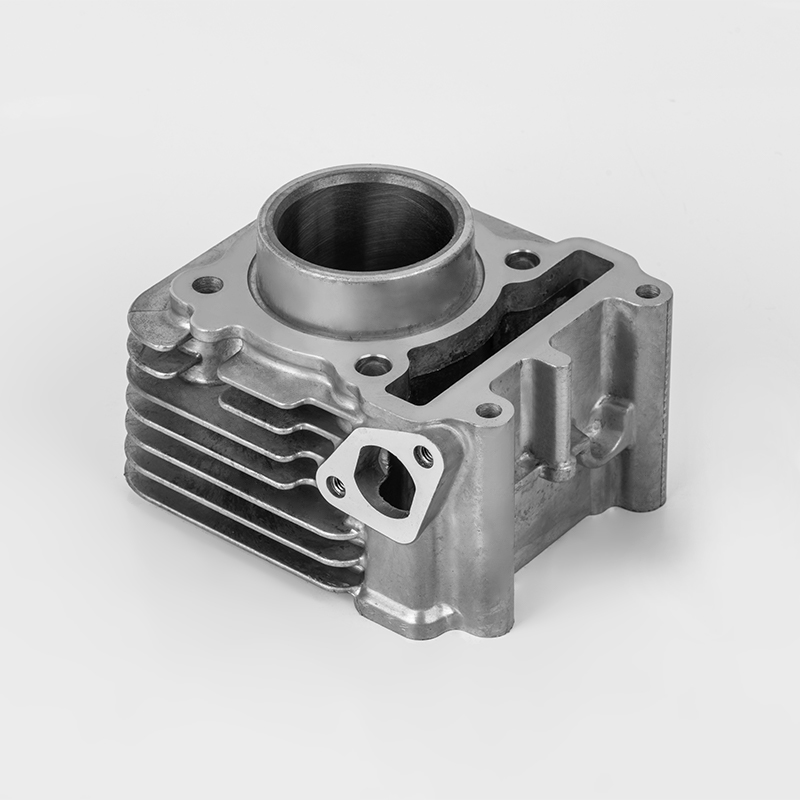

▸Aluminum Alloys

Most common material for modern motorcycles due to its lightweight nature.

Excels at heat dissipation, helping engines stay cooler under stress.

Often used in air-cooled engines (with external fins) or as the outer shell in liquid-cooled engines.

Requires reinforcement (like liners or coatings) since pure aluminum wears down quickly from piston friction.

▸Cast Iron

Traditional material for older or heavy-duty engines.

Naturally wear-resistant and durable under high pressure/piston movement.

Better at retaining cylinder shape (less warping) during intense heat cycles.

Heavier than aluminum, which can affect bike performance and handling.

▸Composite Construction (Aluminum + Iron/Steel)

Combines aluminum’s lightweight cooling with iron's toughness.

Iron or steel liners are pressed or cast into aluminum cylinders for added durability.

Common in engines balancing performance and longevity.

▸Nickel-Silicon Coatings (Nikasil, etc.)

Ultra-hard coating applied directly to aluminum cylinders.

Creates a smooth, low-friction surface that resists wear without liners.

Improves heat transfer and reduces piston drag, boosting efficiency.

▸Chromium Plating

Hardened chrome layer electroplated onto cylinder bores.

Provides excellent scuff resistance and longevity.

Used in high-performance or racing engines where reliability is critical.

▸Specialized Alloys

Some manufacturers use proprietary alloys (e.g., hypereutectic aluminum) for enhanced strength-to-weight ratios.

Engineered to minimize thermal expansion under heat, maintaining precise piston clearances.

English

English Español

Español عربى

عربى